The chip shortage has been hitting companies of all sizes the past year and a half. Smaller companies have the ability to be more nimble, but also have a lot less leverage in the market (and even for some big companies, that leverage is minimal). Jan Malášek, the Pololu president, wrote an impressive and detailed account of the company’s issues, which are by no means peculiar. Some of the details are worth highlighting but the whole post should be read in its entirety.

You might be surprised to hear that our total inventory is actually at an all-time high. And apparently, that is fairly common, even among the biggest companies, including the main electronics distributors. When I was talking to my Arrow Electronics rep last month, he said his warehouse is full. I asked of what, and he said he didn’t know, but apparently not the parts he needs.

Of course the problem with this is that being short a few components doesn’t mean you can make 95% of your catalog. If you have even 10,000 components on 14 out of 15 lines of a BOM, that’s going to let you produce a whopping total of 0 products. And what’s often missing, or what is remarkably missing, are these key components used across parts. When its a common component that’s out of stock, a huge chunk of the catalog is affected.

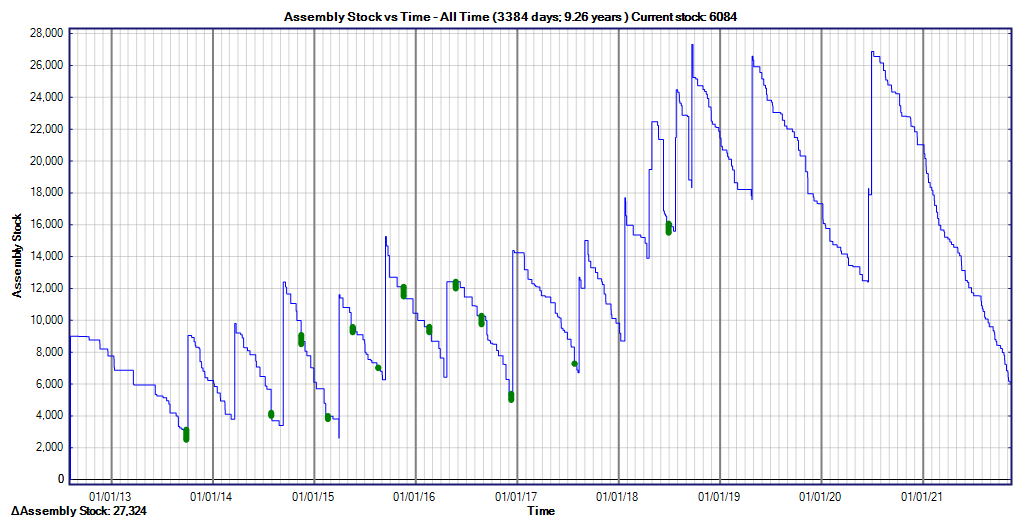

Here is a screenshot from our internal system showing the inventory history of a relatively unremarkable component (a small MOSFET) that we have been using for almost ten years now:

Inventory history for a component with shortages in 2021.

The stock history is representative for a typical component that we gradually put into more product designs so that the rate of usage keeps increasing and the amount of stock we keep on hand gradually increases, too. Usage of this part ramped up in 2018, to around 35 thousand pieces per year. We last received some shipments in mid-2020 that put us in a seemingly-secure place, but the situation became less comfortable as we got into 2021, and the past several months have been downright alarming since we might only have enough parts for two more months, while the estimated shipment dates for my orders are well into 2022. And this is with us putting the brakes on parts usage!

Malášek talks a bit about the causes for the shortages, and while it’s likely exacerbated by supply chain issues, there are other factors at play.

From my talking to manufacturers’ representatives, my impression is that the semiconductor companies are just genuinely facing a combination of increased demand and reduced capacity as the pandemic interfered with their operations that are spread throughout the world. For example, ST was telling me about one motor driver that gets the silicon processed in Italy, then tested (still in silicon wafer form) in Singapore, and then chopped up and packaged in Malaysia. In this one instance, the silicon is done, and as operations resume in Malaysia, they should be able to get me some of the parts by the end of the year. But for other parts from the same company, such as microcontrollers, they don’t even have enough allocated to my general western North America region to meaningfully talk about where in the queue we are.

This is all great perspective and good information to carry with us as we brave 2022 and beyond. Check out the whole post here.